Automatic manifold

The VISMEC automatic manifold allows up to 24 materials to be connected to up to 24 machines. Automated, efficient and energy-saving transport.

Dust remover series

VISMEC dust remover uses static electricity to remove dust from plastic materials. Essential for advanced production, such as the optical industry and electronic consumption.

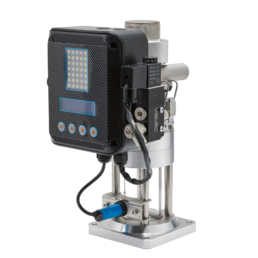

FW 50 Series

Vismec FW 50 is a control system that manages up to 48 feeding stations and one vacuum with emergency reserve. Easy to use, it is connected to a Vismec 4.0 supervisory system.

Halo Series

The HALO weighing ring, installed below the receiver, allows immediate and traceable measurement of the flow rate in kg/h of the loaded plastic material.

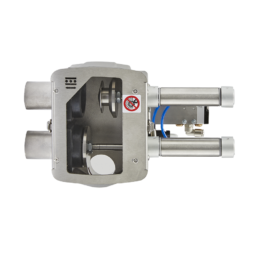

Line cleaning valve series

In the conveying process, the line cleaning valve prevents the plastic material from getting stuck inside pipes at the end of the loading cycle.

Maintenance Hopper Series

VISMEC stainless steel maintenance hoppers, insulated or non-insulated, offer efficiency and easy handling.

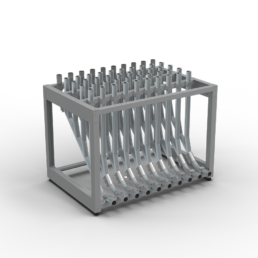

Manual manifold

Manual manifold to support feeding systems in various modular configurations, with stainless steel frames for 5 or 10 reeds.

Ratio valve series

Vismec ratio valves allow two different materials to be conveyed alternately, with a quick, simple and efficient quantity control system.

Receiver base series

Receiver base allows reducing the amount of conveyed plastic material. The base is installed under the receiver or under hopper loader.

Receiver Series

Receivers with different load capacities, from just two litres up to 160 litres. Vismec receivers are made of stainless steel, but can also be ordered in a glass version.

Vacuum Units_VB Series / Cyclone Filters

Wide range of vacuum systems using side blowers and hook pumps. Flexible application including remote, efficient conveying, maximum productivity and reduced maintenance.

Venturi hopper loader

Independent compressed air hopper loader for conveying materials such as masterbatch or granule additives.